Fluidized Bed Powder Coating Explained

There are a few different ways to apply powder coating to a part. The most well-known method is probably application via an electrostatic gun. However, at Job Shop Coatings, we specialize in a different method: fluidized bed powder coating.

This is how the fluidized bed powder coating process works:

First, we make sure the metal part we’re going to coat is clean and ready for adhering. This will often involve a trip through our sandblasting suite and/or a dip in our cleaning tank setup. Once properly abraded and dried, the part may be primed in a chemical solution to ensure full adhesion. After the metal is properly prepared, we preheat it in an elongated belt oven. The metal must be reliably able to withstand a preheat temperature higher than the melting point of the powder coating we’re using.

During or immediately prior to this preheating process, we place the powder coating particles in a house-made container with a porous membrane at the bottom, and force air through the membrane. This causes the particles to rise and become suspended in a fluid-like state.

We then affix the heated piece of metal to a heat resistant rod or hook and dip the whole affair into the fluidized powder coating, keeping it submerged until fully coated, and the desired coating thickness is achieved. This is a time-sensitive process, and each part can have its own particular demands to ensure full adhesion with no marring. Once coated, we remove the part from the fluidized bed, and attach the part to an overhead line for post-heat curing.

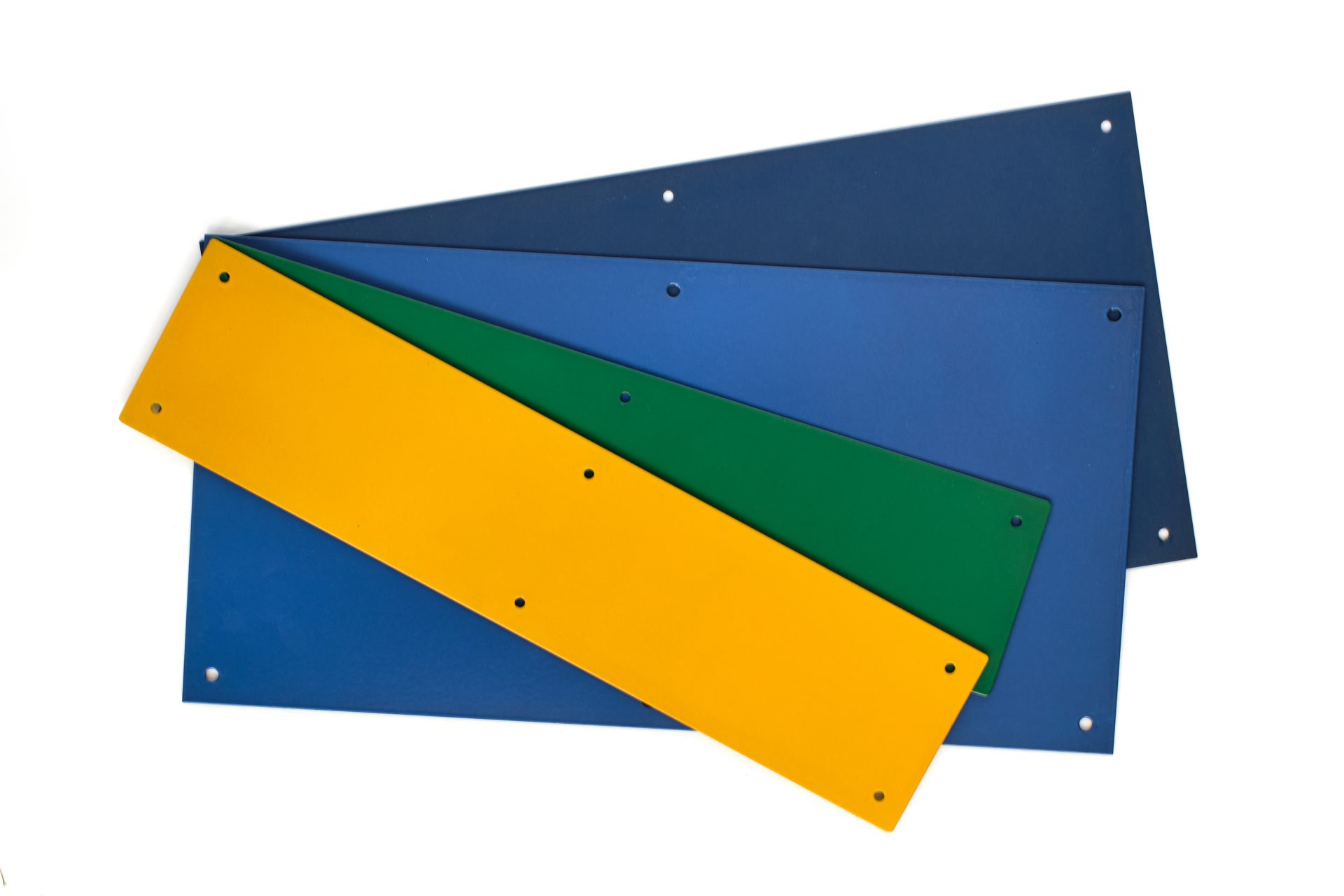

This final post-heating curing process results in a thick, consistent finish providing a number of useful benefits, including extreme durability and excellent corrosion resistance.

If you need fluidized bed powder coating in Indiana, look no further than Job Shop Coatings. With nearly four decades of industry experience, you can trust us to provide high-quality services and unbeatable results. To learn more, contact us today at (317) 462-9714 or jobshopcoatings@gmail.com.